I recently found out how to remove the offset on irons.

Offset means that the front edge (left side) of the hosel is in front of the leading edge of the club when looking down on it at address. It places the center of gravity further back, which 'helps' us to close the clubface in the impact zone.

Offset means that the front edge (left side) of the hosel is in front of the leading edge of the club when looking down on it at address. It places the center of gravity further back, which 'helps' us to close the clubface in the impact zone.

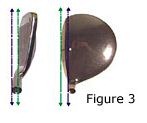

Onset means that the front edge of the hosel is behind the leading edge of the club. The amount of offset or onset is calculated by measuring the distance between the front of the hosel and the leading edge.

Face progression is different in that it is defined as the distance between the center of the hosel and the leading edge. This can be both a positive or negative value.

If you strengthen the lofts on your irons you will typically increase the amount of offset because the hosels will be bent a bit. So when I heard that there was a way to remove the offset on a club I decided to give it a go.

Even though the process is fairly simple I found that it might take some time to get the hang of it. The longer the hosel of the club, the easier it will be to remove offset.

- First you need to bend the loft of the club about 5 degrees weaker. This bend operation must be performed by placing the bending bar at the top of the hosel (where the shafts meets the hosel).

- Then after that you need to perform a 'regular' bend operation, just above the clubhead. Bend the loft back to its original strength.

- Now have a look and see if the amount of offset is less than before. You will probably have to repeat these steps a couple of times before you will get good results; but it will be well worth it in the end.

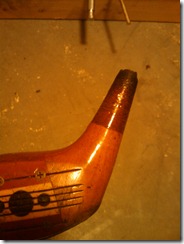

Here are the before and after pics of a Hogan pc5 3 iron: